Wood is the most widespread and ecological material used in furniture making. Each variety and breed has its own advantages and disadvantages. Therefore, the buyer should familiarize himself with them in advance and choose the most suitable type of wood. First of all, it is worth considering the strength of the selected breed, hardness and susceptibility to deformation, wear resistance, oxidation state, and texture.

Advantages of natural wood furniture:

• practicality

• aesthetic appearance

• environmental friendliness

Cons:

• high price

• difficulties in the technical processing of raw materials

• requires special care

• requires an optimal level of humidity

Wood grades for durability are divided into:

Soft (spruce, pine, chestnut, alder, birch, aspen, linden, fir, poplar, cedar, juniper, willow).

The peculiarity of soft types wood is that it is easy to manipulate. But at the same time, it is not resistant to damage and scratches. Many soft rocks lend themselves well to shading, which allows you to change the colors and shades of the material. It is quite affordable and short-lived.

Medium (larch, common birch, oak, cherry, elm, beech, sycamore, walnut, maple, apple, ash).

A feature of this type of wood is its resistance to damage. It is moisture-resistant and amenable to processing. Retains its appearance for a long time. This type of wood is the golden mean between the other two.

Hard (maple, merbau, iron birch, mountain ash, white acacia, hornbeam, dogwood, boxwood, pistachio tree, and most of the exotic species).

The most resistant varieties. They are quite difficult to process and therefore have a fairly high price. Elite furniture is often made from this variety.

By color, light (aspen, cherry, alder, pear, maple, pine, olive, hornbeam, sweet cherry, beech, board), dark (ebony, wenge, bog oak) and red species (walnut, mechagon, kempas, paduk, apricot, larch, merbau, rosewood, eucalyptus). Behind the origin – conifers (pine, spruce, cedar, fir) and deciduous (oak, birch, pear, walnut, aspen, linden, ash, alder, larch, beech, chestnut). It is equally important to consider the individual characteristics of each wood species.

Popular types of wood

This category of wood varieties includes those species that are considered the most accessible. Raw materials of such rocks are easily extracted, they have an optimal price and at the same time are easy to process. Often these types of wood are quite similar to each other and do not differ in special qualities. Most often, these are medium or soft varieties for strength. And also having the most inconspicuous colors.

1. PINE

Pine has a light color and a pleasant pine scent. This timber is quite soft and sticks well. Pine is required for the manufacture of cabinet furniture. It is used with or without varnishing. Its only drawback is its tendency to scratch and damage.

2. SPRUCE

Spruce is mainly used for the manufacture of structures that do not experience significant loads during operation. This can be explained by the softness of this material and its low strength. Spruce sticks just as well as pine. But it is less popular, since it absorbs moisture well, as a result of which it quickly loses its aesthetic appearance.

3. OAK

This timber is considered one of the most demanded. It is durable, fairly easy to work, and does not rot. Has an expressive texture and a wide variety of colors. Practically not affected by microorganisms. Oak is also distinguished by its external beauty. Carving and polishing is difficult, but the end result exceeds all expectations. Resistant to moisture, temperature, and various pests.

4. ASH-TREE

Has high durability and strength. The quality is slightly inferior to oak. Poorly polished and requires mandatory antiseptic treatment. Ash is not resistant to moisture but has an aesthetic texture. It is a fairly popular material in the manufacture of furniture.

5. BEECH

This material is very malleable. It has a beautiful hue and texture. Strong enough and durable, but not resistant to moisture. Curved pieces of furniture made of this material are very popular.

6. COMMON BIRCH

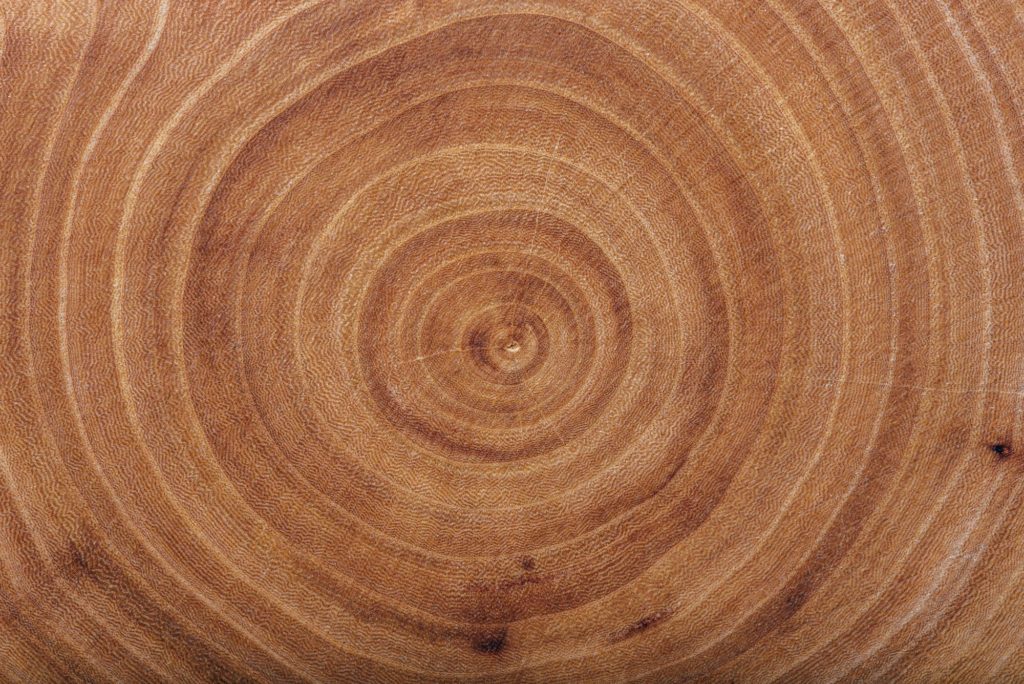

This material is notable for its distribution as it is not difficult to obtain. Birch is very flexible to processing, has a beautiful color, and is quite durable. Birch is not resistant to microorganisms and is prone to rotting. Therefore, it is often used in the manufacture of plywood, rotary cut veneer, chipboard. The value of the breed increases with the age of the tree, due to the appearance of the tree ring contour.

7. WALNUT

The advantage of the walnut is the variety of colors. This material is malleable enough to handle. It is easy to paint and looks beautiful when carved. It is thanks to this property that the walnut is used not only for the manufacture of furniture but also for the decoration and finishing of elite items.

8. YEW-TREE

This timber is distinguished by its strength and durability. Served with processing, but has a large number of knots. It reacts steadily to moisture and atmospheric changes. It is quite common in the manufacture of furniture.

Valuable varieties of wood

This category of varieties mainly includes less popular breeds. They are of great quality and, accordingly, price. The main difference from the popular ones is that this category includes rocks that are more difficult to get. They are distinguished by their durability and variety of textures, unique patterns.

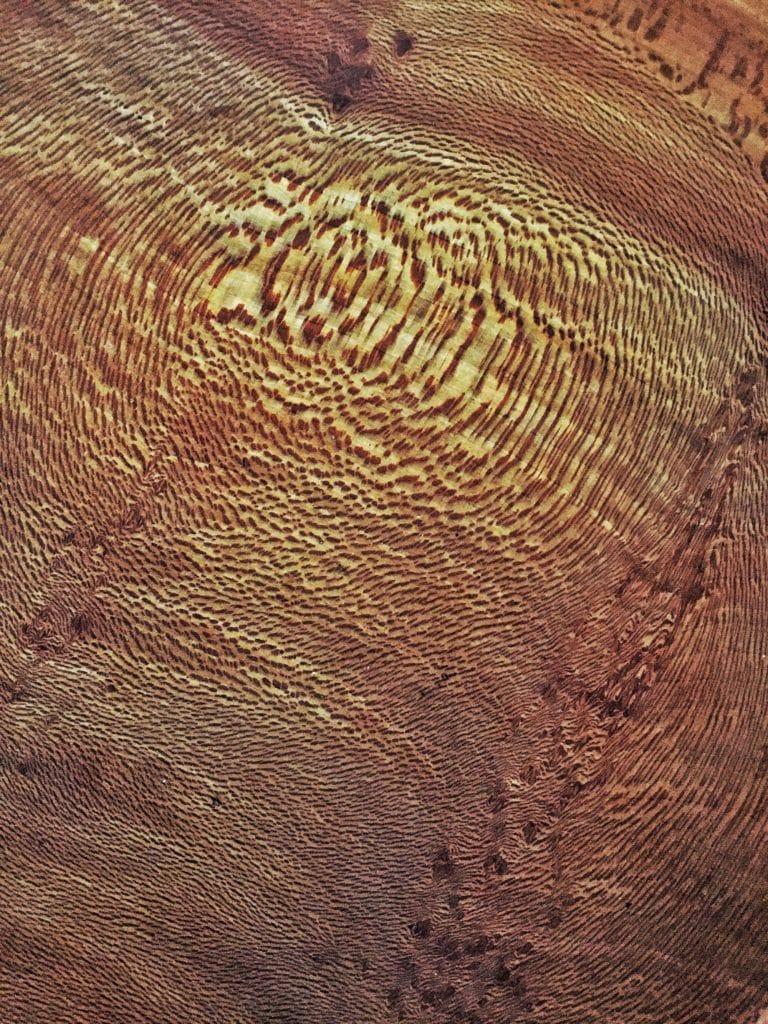

1. CURLY BIRCH IS A VARIANT OF THE PLANT SPECIES SILVER BIRCH (ALSO KNOWN AS WARTY BIRCH, EUROPEAN WHITE BIRCH, OR EAST ASIAN WHITE BIRCH)

The variant originally comes from Karelia in Finland and Russia. It differs from ordinary birch in higher performance indicators. It stands out for its unusual coloring and texture. As a result, it is quite high in price and is used mainly in cladding solid wood furniture.

2. MAPLE

Maple is very malleable. It has a beautiful hue and texture. It is distinguished by its strength and heavyweight. Used as a veneer for facing solid wood furniture.

3. WHITE ACACIA

This material is distinguished by its hardness. Acacia is difficult to process, therefore it is used for cladding soft rocks. It is flexible enough and has high frictional resistance.

4. CHERRIES

This material is quite flexible, it lends itself well to processing. It looks beautiful when carved, but, unfortunately, is not durable. Another minor disadvantage of cherries is that they can darken over time. It is quite common in the manufacture of furniture.

5. CEDAR

This material is often used in rooms with high humidity since cedar is quite resistant to moisture. It is practically not affected by bacteria, but it is prone to rotting. Cedar has a specific smell and poor strength, therefore it is not very popular.

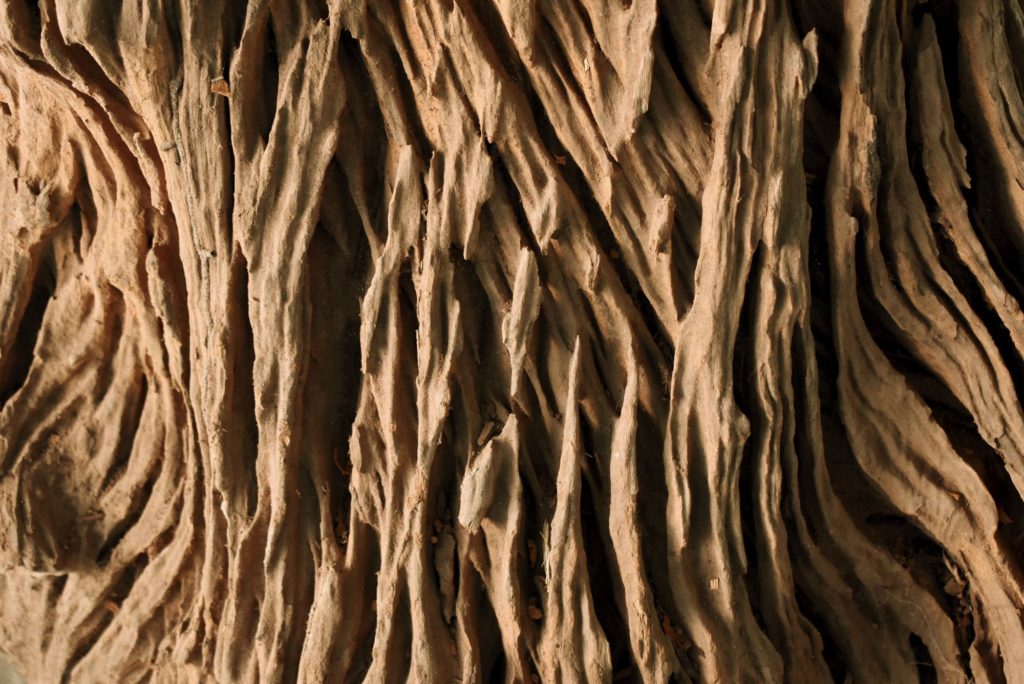

6. LARCH

This timber has many advantages. First of all, larch is strong enough. This allows it to be used both for the manufacture of furniture and as a finishing material. It is resistant to decay and comes in a wide variety of colors. An unusual feature of larch is its positive impact on human health. This breed secretes substances that prevent colds and viral diseases. The disadvantage of larch is the complexity of its processing and a specific smell.

7. LINDEN

It is strong enough and plastic, resistant to moisture, but easily affected by microorganisms. Poor processing, especially staining. It requires mandatory antiseptic treatment, therefore it is not very popular.

8. PEAR

This timber outperforms most other high strengths. The pear is quite durable and has a pleasant coloration. It is easy to process, well colored, polished, and sanded. But at the same time, it should be dried with extreme care.

Elite wood varieties

This category of species includes the most unique and most beautiful types of wood. Basically, the elite varieties mainly include tropical species. These trees have their own distinctive feature or ability. Expensive furniture is made from elite varieties of wood, which will be of high quality and will last a long time. And also most of this species is threatened with extinction.

1. RATTAN

This material is distinguished by its resistance to moisture, first of all, this property is promoted by the place of existence of this tree. Rattan grows in the tropics, as a result of which it tolerates temperature and pressure changes well. This timber is quite plastic. Most of the wicker furniture is made from rattan. There is artificial rattan, a material that was supposed to be a cheap analog, but unfortunately, it is significantly inferior in quality.

2. EBONY TREE

Has a large variety of varieties. The most popular are: Cameroon, Ceylon, Madagascar, Makassar, Munsky, Lunny. Each variety has its own distinctive characteristics. Mostly ebony is black in color. Differs in its hardness and durability.

3. AGARWOOD

This tropical tree is distinguished by the presence of aromatic substances. It is also used in the manufacture of perfumes and medicines and is also rarely used in cooking. Agarwood furniture is quite high in price since this species is threatened with extinction.

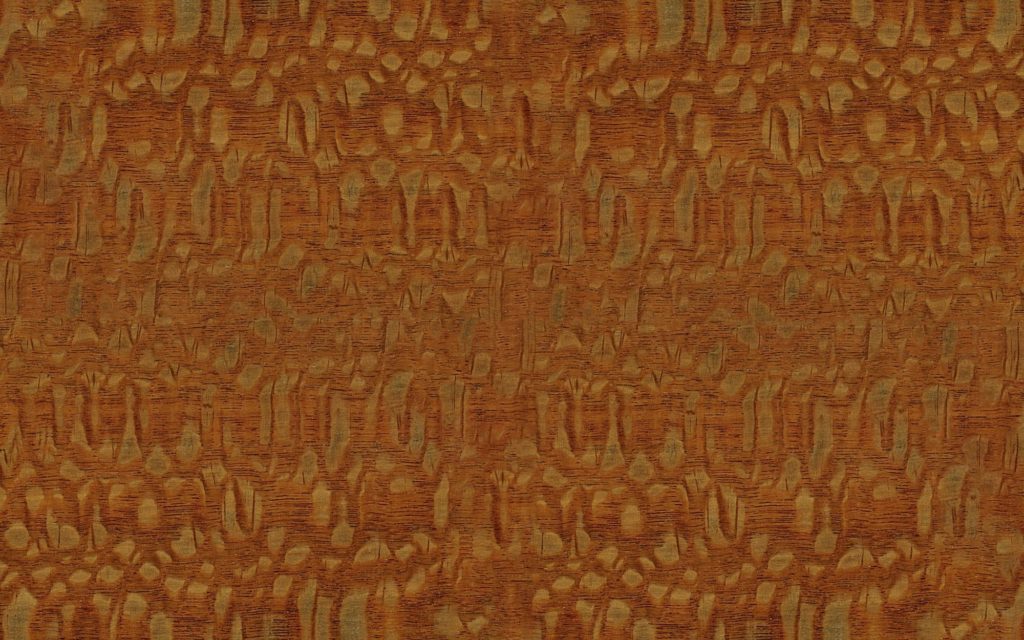

4. LACEWOOD

Lacewood is strong enough, easy to handle, and not prone to rotting. Has a unique texture, heart-shaped patterns on a red-brown background. Carving and polishing are difficult. Resistant to moisture, temperatures, and various pests, practically not affected by microorganisms.

5. TEAK

A timber that is distinguished by its unique color. It lends itself well to processing and is quite durable. It has an expressive texture and pleasant warm shade, due to which it is classified as a mahogany species.

6. BAKOTA

A rare exotic breed that is distinguished by its unusual coloration. It lends itself well to processing and has a high density. Bakota is resistant to decay and various pests. This material is quite durable.

7. SANDAL

Differs in its aromatic substances. Sandalwood, like agar, is used to make perfumes and oils. Also, this timber has useful properties that have a positive effect on human health. Furniture made from such wood is quite expensive since sandalwood is endangered.

Depending on defects and damages, the following types of wood are distinguished: selected grade, 1, 2, 3, and 4 grade. It is determined on any one-meter section of the board length for each side. The quality of lumber is determined by the worst side.

Selective grade (class “A”)

This variety is practically not used for making furniture. It is useful in larger buildings. They are mainly used in shipbuilding and automobile construction. Differs in fairly high valuable and good quality. The number of cracks on it is unacceptable more than 10%. This material has practically no flaws. Knots are only allowed at a distance of 2 meters and small.

1st grade (class “B”)

This variety is less expensive and is used in the manufacture of furniture. Small knots and cracks with a depth of more than 1 mm are permissible on it. This variety is wood without rotten elements and rottenness, gray areas, mold, or the inclusion of foreign parts.

2nd grade (class “C”)

This grade is often used in the manufacture of upholstered furniture frames. It is characterized by the presence of small flaws, which, in general, do not spoil the general characteristics and appearance. Small knots and cracks may be present. Rottenness, dead bark, and parts affected by parasites are strictly not allowed.

3rd grade (class “D”)

The level of wood is rather low in quality. It is mainly used in the packaging industry. Large intergrown knots and end cracks are not allowed, to the full depth. All other flaws are available.

4th grade (class “E”)

The lowest grade of wood. It is characterized by all the shortcomings and is often used for secondary production.

It is also worth remembering that there are different ways of processing wood, among them are:

• Dyeing (often used to preserve the natural colors of the material)

• Staining (the main goal is to increase the strength of the material and protect it from mechanical stress)

• Resin (protects the material from decay, while giving a more aesthetic appearance)

• Coating with varnish (helps to preserve the natural color, while protecting against fading)

• Coating (protects against high temperatures)

Chipboard, medium-density fiberboard (MDF), and hardboard are still very popular among building materials made of wood.

Chipboard features

A chipboard is a material that is obtained by pressing small wood chips and gluing them together with glue. It is actively used in the manufacture of furniture. First of all, the appearance of a chipboard has a positive impact on the environment. Due to the use and processing of wood waste into a technological and cheap material, forest destruction has been reduced by 50%.

Moreover, in terms of convenience and economy of use, chipboard is very much superior to wood. The manufacture of chipboard products requires a minimum of operations. It is easy to use and does not react to atmospheric changes, unlike wood. This material is quite popular in the manufacture of furniture.

Features of MDF

MDF (fine fraction) is a medium-density fiberboard, it differs from chipboard in that it is made of smaller particles. In the modern world, MDF is gaining more and more popularity. It is fully consistent with the qualities of wood, but at the same time, it is much cheaper in price and at the same time durable. Designers are increasingly preferring furniture from this material.

Features of fiberboard

Fiberboard (fibreboard) is a material made from compressed wood dust, which is created by wet pressing. This is a fairly thin slab with a mesh texture. On one side it is covered with a film. Of course, this does not allow using it for the complete manufacture of furniture, but for some parts, it is quite a good and reliable option.