How many times, entering a furniture store and looking at furniture, have you wondered: how to figure out these sets of letters on the price tags – chipboard, fiberboard, MDF? How do these abbreviations differ in general, why complicate the already difficult process of choosing the right furniture at all? Why is a sheet of plywood more expensive than a sheet of chipboard, although they look almost the same?

Well, let’s try to quickly figure out what are the differences between these materials, why you need to understand the difference at all, and also determine how they are similar.

Chipboard – inexpensive and durable.

Chipboard – chipboard, which is made from sheets of sawdust, shavings and dust. Formaldehyde resins serve as a binder, the resulting board is usually laminated with a film. This is done for several reasons: firstly, to protect the board from moisture and other harmful influences, and secondly, the film prevents the release of harmful formaldehyde into the external environment.

There is a safety classification based on the concentration of formaldehyde, according to which classes are considered safe: E1 (European standard), E 0.5 (also complies with European standards). It is strictly forbidden to use: E2, E3.

When buying furniture, do not hesitate and ask the seller’s safety class and ask for certificates. Remember, this is about the health of your loved ones and your health.

One of the varieties of this material is chipboard (laminated particle board). Chipboard differs from chipboard by the presence of the top layer – laminated film. It can have a wood texture, it can be of different shades, so now chipboard is widely used in the production of furniture: tables, racks, shelves – everything that you can imagine.

Of the pros, I would like to highlight:

- The material has a low price;

- Chipboard provides the best sound and heat insulation properties;

- The material is resistant to bending, allows you to give different shapes;

- With the help of chipboard, they level the surfaces and give them strength and strength.

Minuses:

- The composition includes harmful resins, the availability of which must be checked with the manufacturer;

- Particleboard is difficult to repair.

Anyone who is not afraid of temperatures and bacteria – MDF

MDF is a board made from fine sawdust and dust. In the production of this material, paraffin and lignin are used, this approach ensures complete safety when choosing. Simply put, MDF is completely harmless to humans.

MDF is widely used in the manufacture of carved facades, cabinets and floor coverings. In China, MDF is often the material from which gift wrapping and gift containers are made.

Positive sides of MDF:

- The ability to apply patterns;

- Good moisture resistance and resistance to temperature extremes – a good option for the bathroom and kitchen;

- High strength and ductility;

- High protection against fungi, bacteria and other harmful microorganisms.

Let’s pay attention to the cons:

- MDF facades are susceptible to chemicals, so it is worth avoiding particularly powerful cleaning agents;

- Flammability: MDF facades are much easier to ignite than natural wood.

Fiberboard – pay attention to the back of your favorite cabinet

Fiberboard (Fibreboard), which is also called hardboard, is obtained by pressing a mixture of wood fibers, water and synthetic additives. Basically, this material is used for the manufacture of back covers for drawers or furniture, respectively, the requirements for high strength, wear resistance disappear. By analogy with laminated chipboard, a laminate film can be applied to fiberboard.

Let’s highlight the positive aspects of the material:

- Moisture resistance (due to paraffin and rosin in the composition);

- Very low price;

- The fiberboard plate is capable of bending.

Taking into account the peculiarities and, in general, the application environment, it is not difficult to determine the negative aspects:

- Low strength;

- Not too high quality;

- Low strength.

In addition, when purchasing fiberboard products, as well as when purchasing chipboard, it is imperative to check with the seller for the availability of certificates of conformity of products to GOSTs. Don’t close your eyes for this moment.

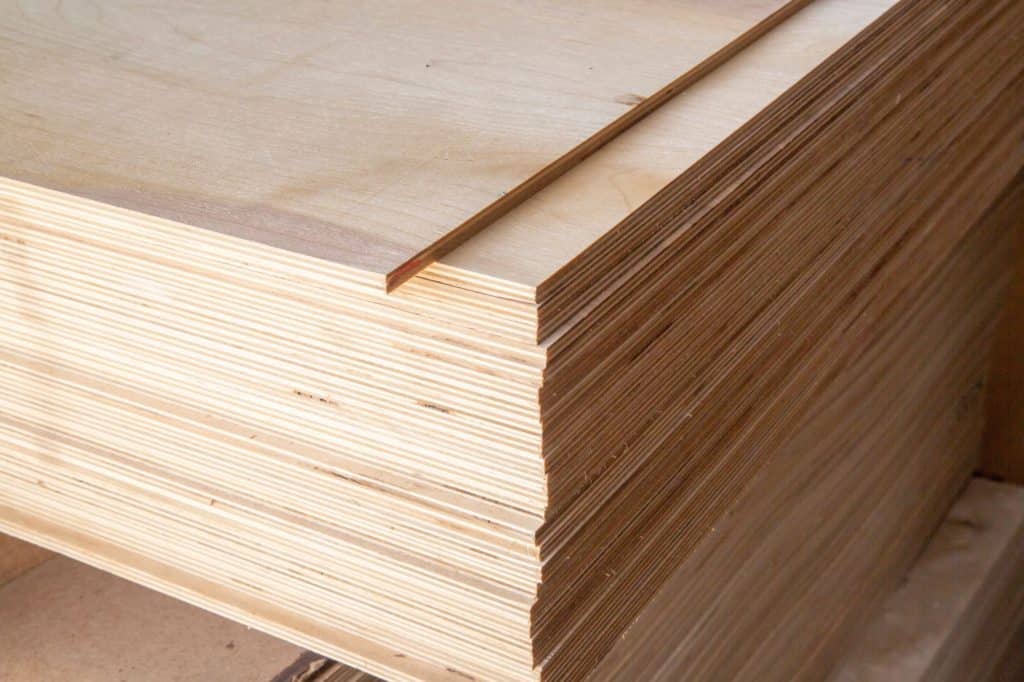

Plywood is reliable, high quality and aesthetically pleasing.

Plywood consists of layers of veneer that are firmly glued together. Simply put, plywood is made up of thin sheets of wood and interlayers.

With the help of plywood, like chipboard, they level and insulate the surface, it is a key material for ensuring a durable and durable coating. Depending on the type of wood used as a material for manufacturing, plywood is subdivided into coniferous and birch.

Plywood has received a high range of applications in the interior. It is used in the manufacture of window sills, soundproof panels, as a cladding in the manufacture of doors.

It gained incredible popularity in the furniture industry. Cabinets, tables, shelves, shelves, country furniture, kitchen and garden furniture are of high quality.

Already impressive, but did you know that plywood is also used to make gift boxes and boxes for perfume, dishes, watches, bottles or even jewelry? What about sports areas? Yes, slides, skateboard slopes, catamarans seats – all of this is also made of plywood.

Positive aspects of plywood as a material:

- Resistant to abrasion, durable;

- Withstands mechanical stress well;

- Very moisture resistant;

- Fasteners do not destroy the structure of the material, they hold well;

- Looks aesthetically pleasing, cover it with varnish and enjoy a noble and pleasant look.

But even such a good and high-quality material has only one, but rather significant disadvantage – high cost.

Summing up, I would like to give a convenient comparative description of all materials in the following table.

| Material | Cost | Durability | Environmental friendliness | Moisture resistance | Other |

|---|---|---|---|---|---|

| Plywood | More expensive than the rest | High | Completely environmentally friendly | High | Expensive, but very high quality material with high performance. |

| Chipboard | Low price | High | Harmful resins in the composition, the availability and quality of which must be checked with the manufacturer. | High | Despite the heavier weight, the density is less, the material is easier to cut.High sound and heat insulation properties. |

| MDF | Low price | High | Completely safe for human | Good | Has a high protection against harmful bacteria, fungi and microorganisms. |

| Fiberboard | Very low price | Low | It is worth checking with the manufacturer the concentration of resins in the composition | Low | The main application is the manufacture of back walls for furniture, drawers. |